Process and quality assurance in laser material processing

01.03.2024

Vision systems from ACI Laser are the key to process and quality assurance in laser material processing. By tailoring the systems to the individual needs of customers and using state-of-the-art technologies such as the AOI vision system, process control can be optimized and product quality significantly improved.

Vision systems: The key to increasing efficiency in industry

In today’s fast-paced industrial landscape, vision systems have become essential for image capture and processing. ACI Laser responds to the growing demand for customized solutions by offering a range of camera options specifically designed for the diversity of marking objects. These camera systems are equipped with different lighting scenarios and provide users with a crucial tool for monitoring and fine-tuning their manufacturing processes.

Optimization of process control through tailor-made solutions

ACI understands that no two industrial companies are the same. That’s why we offer customized vision system adaptations to meet a wide range of requirements. With a selection of lighting scenarios and camera options that can either be externally adapted or integrated directly into the beam path of the laser head, ACI Laser ensures that process control is optimized for each customer.

Automatic object detection with the AOI vision system

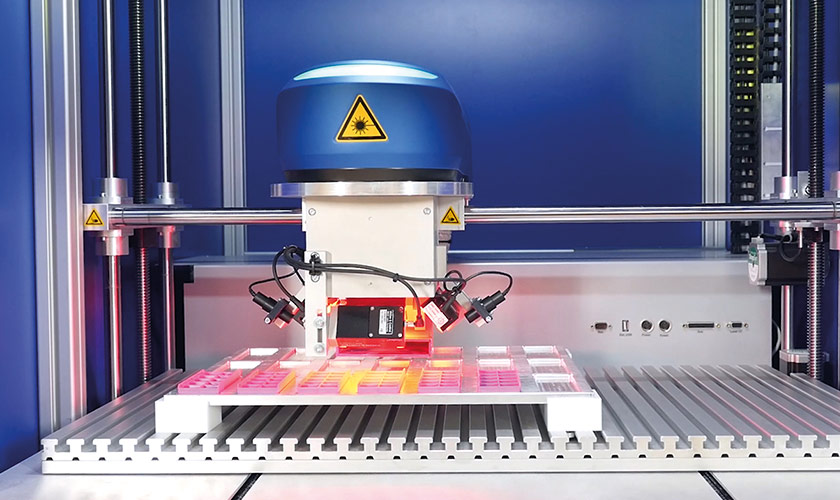

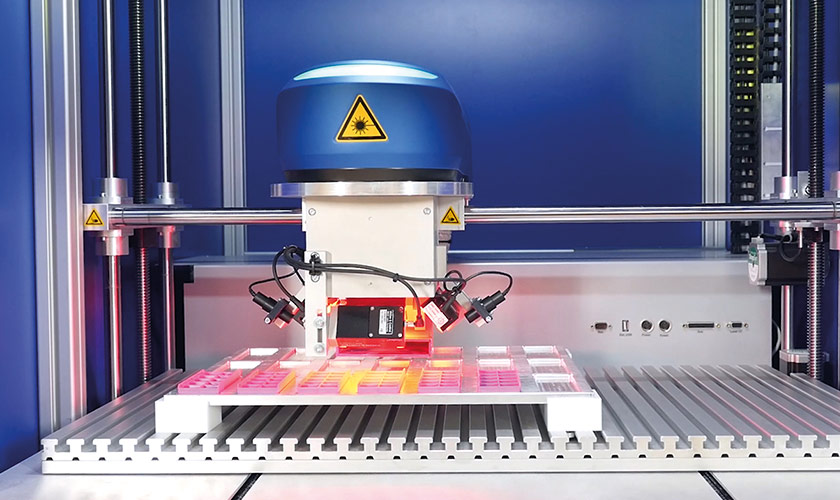

With the AOI (Automatic Object Identification) vision system, we offer a high-end camera solution for customer-specific requirements for image processing and evaluation in laser material processing. The AOI enables the fully automated detection, identification and measurement of objects, texts and codes, even with complex geometries. The vision system captures and analyzes the marking area in real time using a sophisticated camera system, thus contributing to quality and process reliability.

Marking laser DFL Ventus Marker with AOI of the Economy Fiber series

Quality assurance through precise laser marking

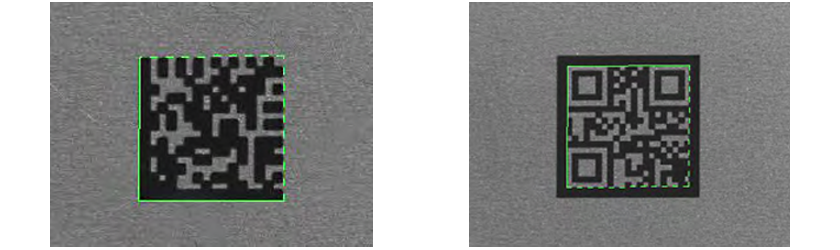

Another milestone is the ability of the AOI vision system to read and verify 1D and 2D codes as well as OCR (Optical Character Recognition). The laser marking is automatically aligned with the object and verified after the marking. This combination of object recognition and laser marking makes a significant contribution to quality and process reliability and creates reliable process control for a wide range of applications.

2D barcodes: DataMatrix code and QR code

OCR (Optical Character Recognition)

Combination of object detection and laser marking

The combination of object detection and laser marking is an excellent way of contributing to quality and process reliability and ensuring reliable process control for numerous applications. By using an AOI vision system, complex processes can be automated and the error rate significantly reduced. This technology takes them to the next level.