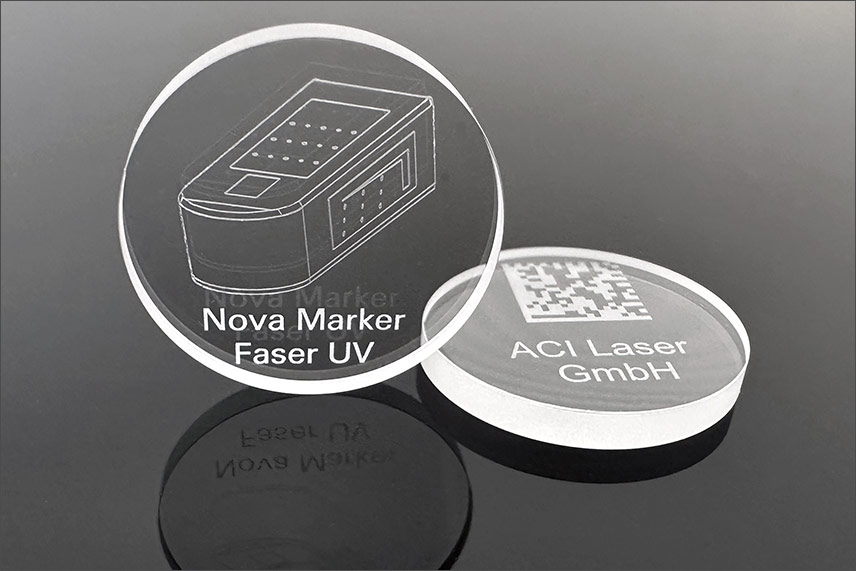

ACI presents new UV fiber laser DFL Nova Marker

23.09.2025

ACI Laser is expanding its successful Business Fiber series with the powerful fiber laser in the ultraviolet wavelength range of 355 nanometers. This short wavelength enables so-called “cold material processing”, in which thermal influences on the workpiece are minimized – ideal for applications that require maximum precision and gentle material processing.

The DFL Nova Marker was specially developed for demanding marking and engraving applications. It is characterized by its versatility with materials and is ideal for marking plastics, ceramics and for fine engraving on metals. In addition, the new UV fiber laser offers optimum conditions for high-precision fine cutting and structuring processes, for example in microelectronics, semiconductor production or medical technology. Particularly sensitive materials can be processed with the DFL Nova Marker without contact, permanently and particularly gently.

Fine structuring on brass

Versatile UV fiber laser for greater efficiency and top quality

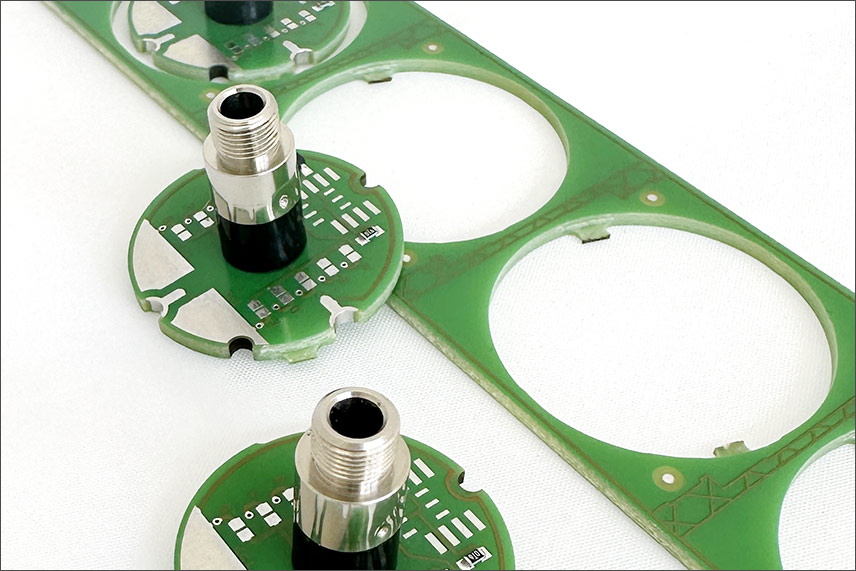

The modern UV fiber laser technology is suitable for cross-industry use on a wide range of materials. Typical areas of application for the DFL Nova Marker can be found in the electronics industry for marking and structuring PCBs, chips and sensors as well as depaneling PCBs. It is particularly noteworthy that the DFL Nova Marker achieves clean edges with no burn residue and consistently repeatable quality, which sets it apart from comparable laser technologies such as standard fiber lasers or solid-state lasers. Laser depaneling is a cost-effective alternative to mechanical methods, especially for small quantities and short cycle times.

Clean, smooth cut edges without smear marks

Gentle, “cold material processing”

In medical technology, the UV fiber laser DFL Nova Marker is used for permanent and durable laser marking of surgical instruments and implants. Very short laser pulses with high peak pulse powers generate high power densities, so that the material is transferred almost directly to the vaporization state, so-called “cold material processing”. Short laser pulses in the lower nanosecond range enable a wide range of materials to be processed extremely gently and cleanly. In this respect, the DFL Nova Marker is an inexpensive alternative to high-priced ultrashort pulse lasers.

Deep engraving on ceramic

High-quality laser processing of ceramics and organic materials

The DFL Nova Marker achieves high-quality marking and texturing results on plastics and glass. Due to the wide variety of materials used in the plastics processing industry, it is important that the laser beam is well absorbed by the material. Additives, fillers or pigments are usually added to the material for this purpose. The DFL Nova Marker produces a permanently durable marking, usually without laser additives, and therefore stands out significantly from conventional infrared lasers in the 1064 nanometer wavelength range. High-quality black markings and color changes can be created on ceramics with the DFL Nova Marker. The UV fiber laser DFL Nova Marker has a clear advantage, as it can also cut ceramics. Laser engravings with the DFL Nova Marker are characterized by burr-free edges without any burning of the material or melting marks. In addition to plastics, wood can also be marked and cut with extremely high contrast, precision and speed without the formation of flames. The DFL Nova Marker UV fiber laser has a significant time advantage over a conventional infrared laser system.

Material-friendly glass engravings

Fine cutting and structuring with UV light

Precision mechanics also benefit from the precise UV fiber technology. Here, the DFL Nova Marker is ideal for fine cutting and structuring optical, electrical and mechanical components. The DFL Nova Marker offers a considerable speed advantage, especially on metals. Due to the very short wavelength of the UV light (355 nanometers), the laser can be focused very finely and the material is only subjected to minimal thermal stress. This enables extremely delicate, burr-free structuring on a micrometer scale without material deformation.