A satisfied ACI customer |

Precise and efficient

Application-oriented and secure

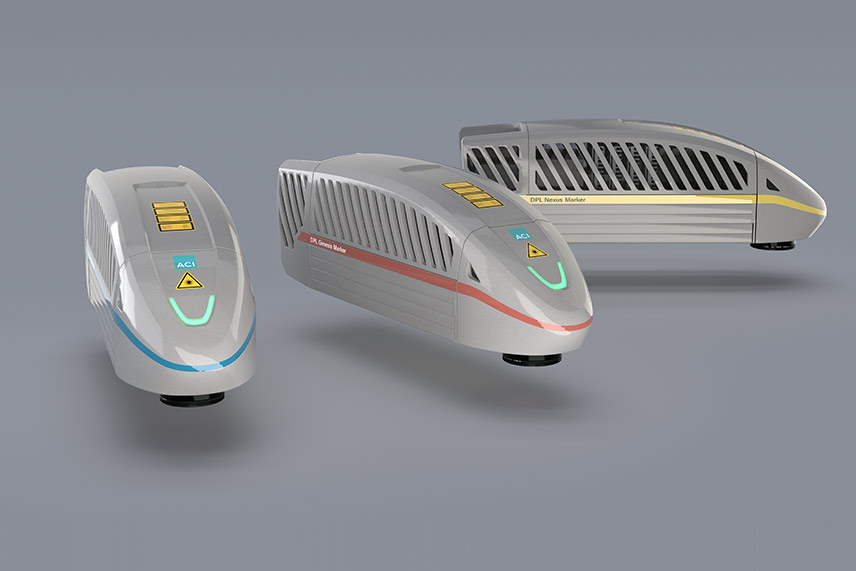

Our wide range of marking lasers offers a solution for almost all areas of application and materials. All laser systems are equipped with a safety device (SD) certified to EN ISO 13849 in accordance with the requirements of functional safety and thus guarantee the user the highest possible protection against malfunctions and a safe condition of his laser system (PLe Cat. 4). The most suitable laser is always selected together with the customer on an application-oriented basis according to the following criteria: Material properties, cycle time requirements and budget.

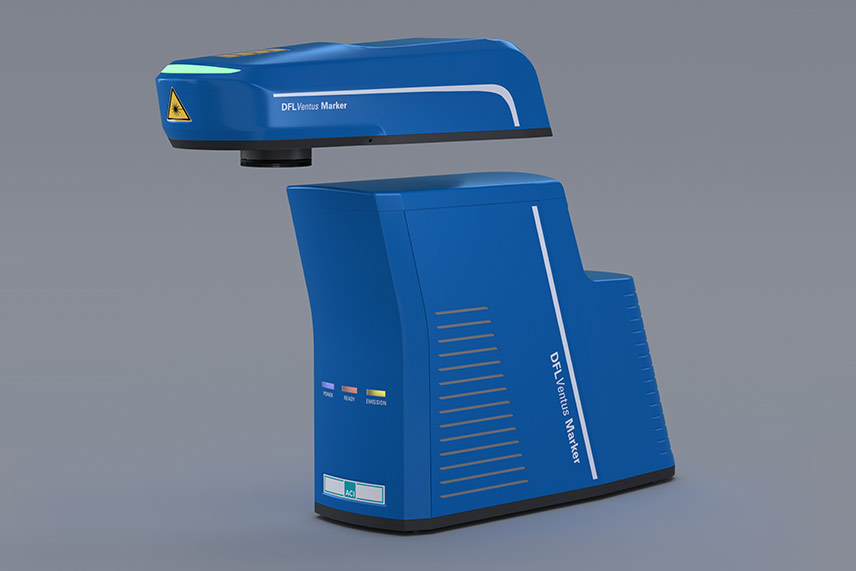

The Business Diode IR series lasers are the all-rounders from ACI. Thanks to their high energy efficiency and beam quality, they are suitable for marking everything from individual parts to large-scale production. These laser systems are typically used in manual workstations for marking entire pallets of workpieces or in an automated line.

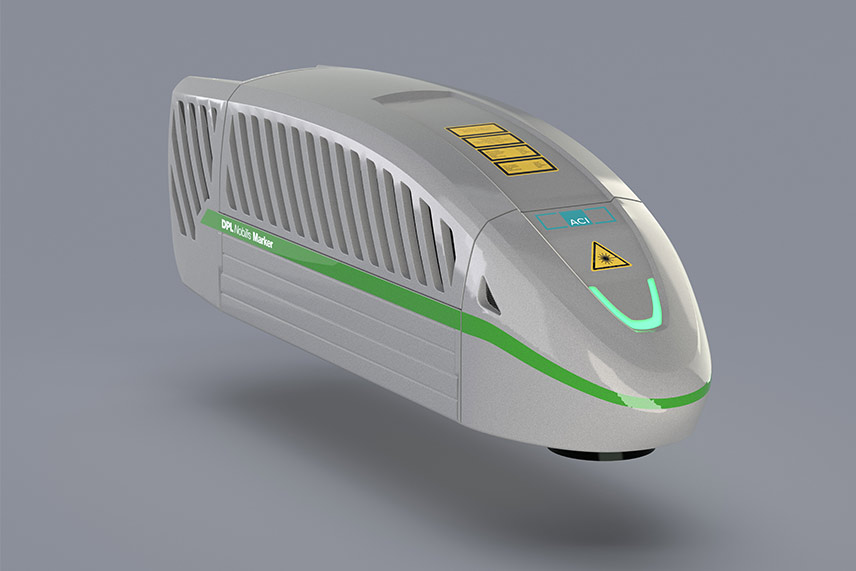

The diode-pumped solid-state lasers in the Economy Diode series are ideal entry-level systems for small and medium-sized companies with manageable marking requirements. Depending on the application and the marking time available, you can choose between different performance classes.

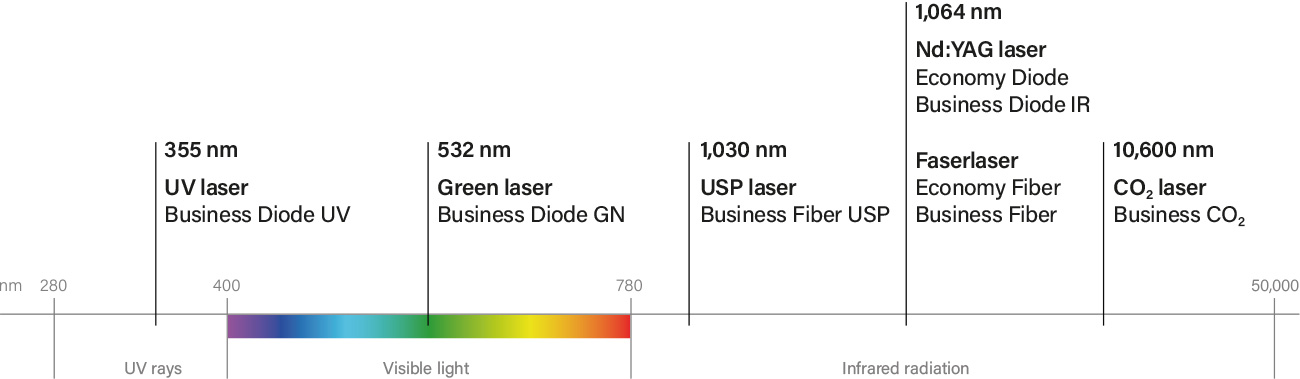

The UV lasers in the Business Diode UV product series operate at a wavelength of 355 nanometers in the ultraviolet spectral range. High-quality marking results can be achieved on a wide range of organic and inorganic materials using so-called “cold laser marking”.

The Business Diode GN series laser systems are diode lasers with a wavelength of 532 nanometers. With “green lasers”, markings can also be made on materials that are difficult or impossible to mark in the infrared range.

The lasers in the Business Fiber product series are ideal for marking metals. Thanks to their excellent beam quality and variable pulse widths, our powerful fiber lasers can achieve outstanding marking results.

The lasers in the Economy Fiber product series are easy-to-use, robust laser marking systems in accordance with laser class 4. They are ideal entry-level systems for laser material processing with fiber laser technology for standard applications.

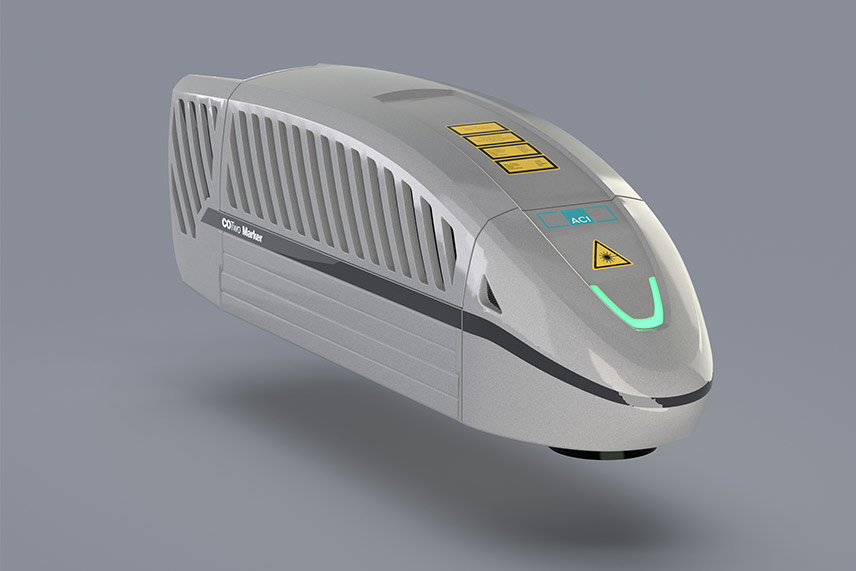

The gas lasers in the Business CO₂ product series are among the most powerful and most frequently used lasers in industrial material processing alongside solid-state lasers. They are primarily used for cutting and engraving.

Laser marking is the ideal solution for permanently marking your products. Unlike printing, which is only applied superficially, laser marking changes the material itself through melting or color change. This makes laser marking durable, abrasion-proof and therefore tamper-proof, even under adverse conditions.

Laser marking does not produce any waste materials, as is the case with stamping with ink or similar processes. No auxiliary materials or additives are required. There is also no need to produce matrices and similar templates. The marking can be flexibly adapted at any time using the laser software.

Our marking lasers are ideal for integration into existing production lines or for manual workstations. We offer both cost-effective standard products and customized special solutions that can be optimally adapted to the individual requirements of your production. Our in-house laser software makes it easy and convenient to integrate our marking lasers.

Over the last 30 years, a class of small marking devices has established itself in the industry for material marking – marking and engraving with laser marking devices or engraving lasers for abrasion-resistant results. At present, the focus is increasingly shifting to codes that are applied to the material using a marking laser.

Depending on the area of application, laser marking systems are designed for manual or automatic operation. A laser marking system with an automatic lifting door is suitable as a manual workstation if a high degree of flexibility is required for individual applications with full control of operation. An automatic laser marking or laser engraving system, on the other hand, is suitable for many consistent applications.

The complex design makes it possible: laser engraving systems are ideally equipped for integration into a production line. They are often equipped with laser accessories such as a rotary unit or a multifunctional camera as a positioning aid in the work area.

In contrast to diode lasers, which everyone knows from laser pointers, fiber lasers, CO₂ lasers, Nd:YAG and Nd:YVO4 systems tend to be used for laser marking of materials and their surfaces in the marking process.

As a compact machine, the industrial marking laser is ideally suited to customer-specific requirements for the marking process (labeling) of materials such as plastic, ceramics, glass, metal, wood, leather, foils or paints. Modern marking lasers offer solutions for almost all product surfaces. For example, annealing marking has not yet been possible with any other technology.

During the marking process, the laser parameters – such as laser power, frequency, pulse width, etc. – can be individually adjusted to meet different customer requirements in order to achieve marking of the highest quality and in the required cycle time.

Marking lasers are suitable for use in all relevant industries. For example, they are used in mechanical engineering, the electronics industry, aerospace, the automotive industry and medical technology. Laser marking ensures the complete traceability of components and products.

Marking lasers are very well suited for high-contrast marking of plastics and metals (e.g. stainless steel, aluminum), but wood, ceramics and glass can also be marked in this way.

In laser marking, a beam of focused and amplified light is used to heat the surface of a material. Depending on the exposure time, different interactions occur on the surface, as a result of which the material is perceived in a different color, for example, or part of the material is vaporized.

This creates a permanent marking.

A diode laser generates the light of the laser beam using a diode, i.e. a semiconductor component, whereas a fiber laser uses a doped glass fiber. For technical reasons, the beam of the diode laser is wider, which makes it particularly suitable for flat applications. Fiber lasers, on the other hand, have a narrower beam and are faster, which is why they are particularly suitable for laser marking in large-scale production.

Press ENTER to confirm or press ESC to close