Magic Mark

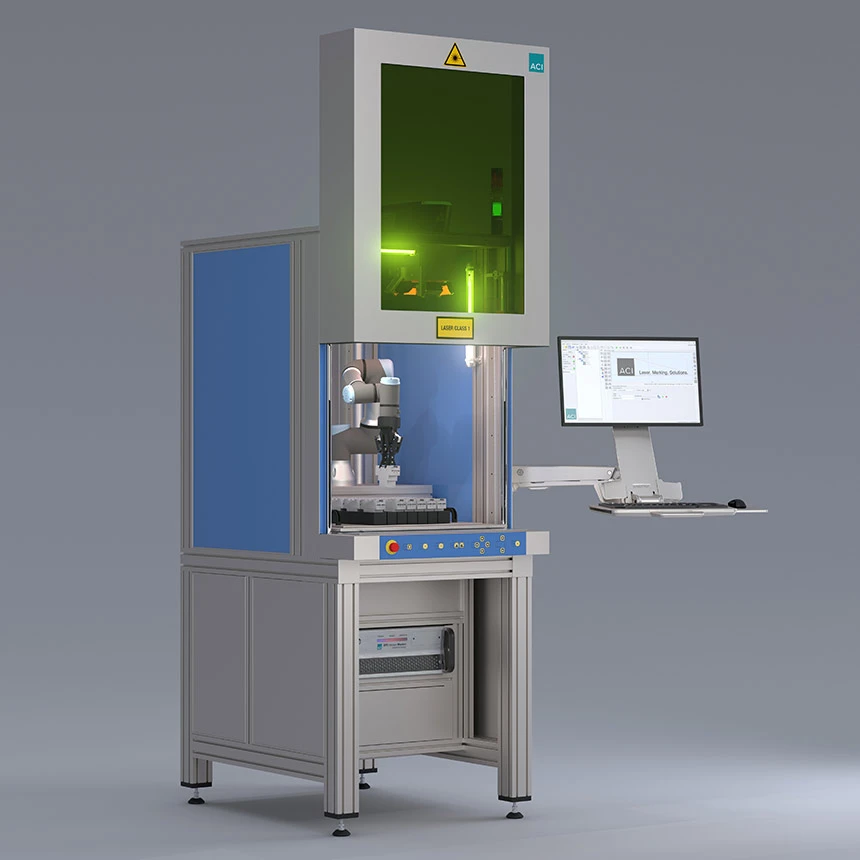

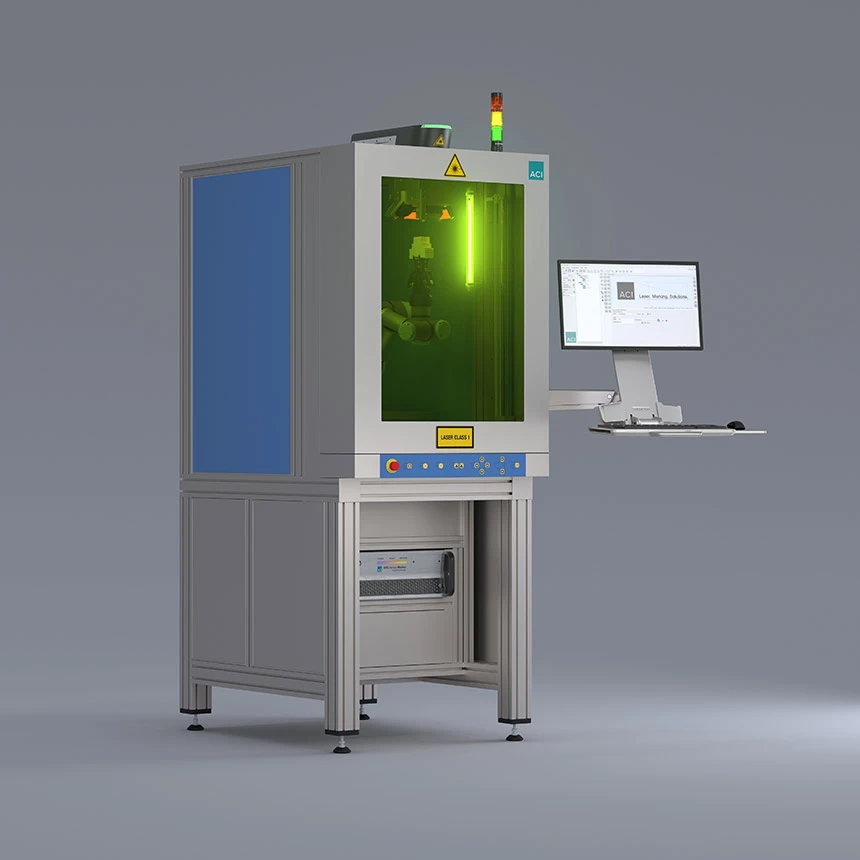

The modern software architecture of the Magic Mark laser software enables targeted access to all available functions and allows users to control the laser and laser peripherals (workstation, axis of rotation, etc.).

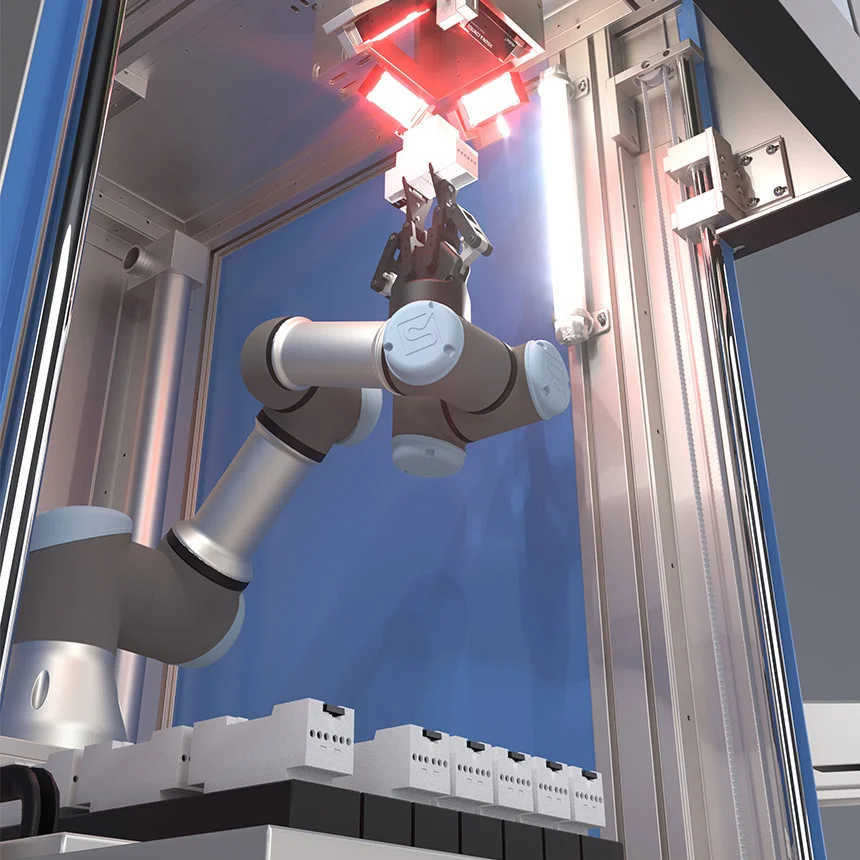

The Sockets plugin provides the connection (interface) between the robot and the Magic Mark laser software and is responsible for sending control commands.

The Control plugin is used to control and implement the entire program sequence of the robot from Magic Mark.

Internal programming

VB.Net [Winwrap Basic] integrated into Magic Mark V3

External programming

C#.Net [MS Visual Studio], access to class library

More about laser software