Laser marking under high pressure

30.07.2025

Hose assemblies with laser-marked stainless-steel fittings and grounding cables

ACI Laser developed a customized software solution for the laser marking of press fittings for its customer Alfotech, which optimally guarantees the semi-automatic operation of the laser system. The complete solution, consisting of a laser system and software, meets all requirements in terms of database connection, cycle times and marking quality despite the demanding conditions involved in pressing the fittings.

Efficient laser marking of press fittings

For more than 40 years, Alfotech has been a successful B2B supplier of technical components such as industrial hoses, mechanical seals and fittings for the production of food, medical and chemical products and much more. ACI has a long-standing, solid partnership with the Danish wholesale company.

A decisive advantage of industrial laser marking is the durability and robustness of the marking result. In addition, laser marking is a processing method that is gentle on materials as it is contactless. However, if the material on which the laser marking is located is severely altered by mechanical stress, this can also lead to damage to the marking.

Laser-marked stainless steel fittings from Alfotech

High-quality marking results despite maximum stress

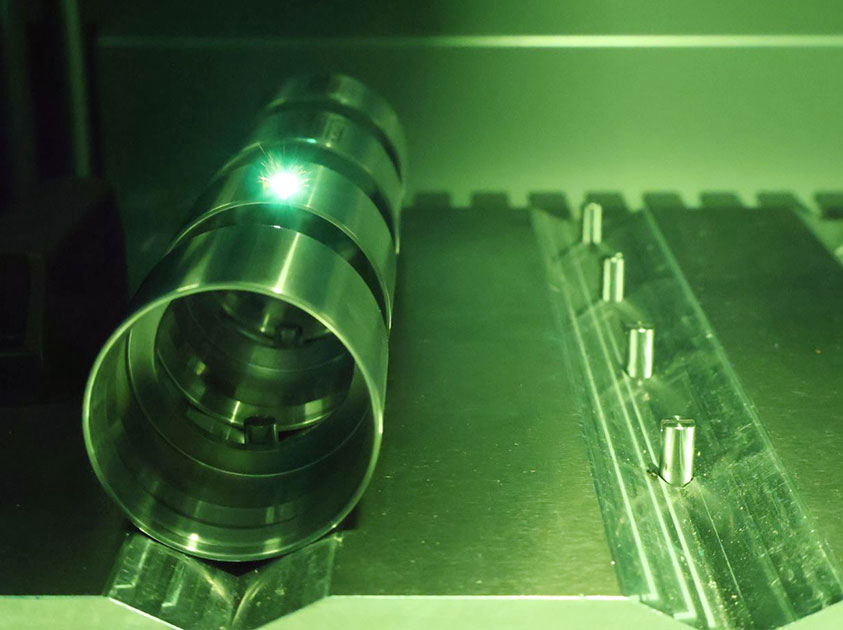

Stainless steel fittings are connection components used in industrial hose assemblies. They typically consist of a connection piece and a crimp ferrule, which are pressed together using a hydraulic hose crimping machine. These are also known as press fittings, and laser marking is applied before crimping to ensure traceability. The material is greatly altered, which consequently affects the quality and legibility of the laser marking. Under these conditions, it was necessary to determine the optimum parameters for the laser system so that the laser marking on the fittings is still of high quality and legible to the human eye even after pressing.

Laser marking process

Extensive sample tests and optimal parameterization

Extensive sample tests were carried out in ACI’s in-house application laboratory to determine the most suitable laser system for the application. Together with Alfotech, ACI carried out extensive parameter tests during delivery and commissioning of the customer’s system to ensure the best possible marking results. All requirements with regard to the quality and legibility of the marking results were met.

Stainless steel ferrules before (left) and after (right) crimping

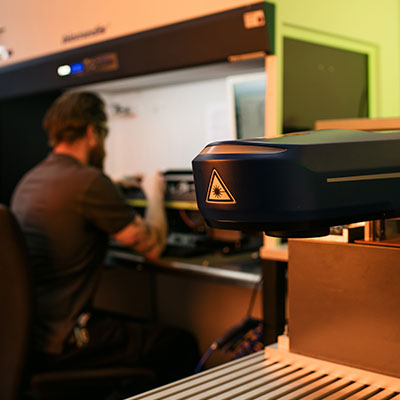

Compact laser marking station with powerful fiber laser

The high-quality laser engraving on stainless steel, which is realized with a DFL Ventus Marker, consists of customer logo and plain text with article number, customer reference number and production date. The fiber laser system from the Business Fiber series has an output of 50 watts and is ideal for fast, precise and robust marking of metals. Marking lasers from ACI can be used in a manual workstation or as an integration component in an automated production line. At Alfotech, the press fittings are marked on pallets in semi-automatic operation in Workstation Professional. The flexible laser station is ideal for processing large quantities and components due to its large working area.

Laser marking station at customer site: Workstation Professional with fiber laser DFL Ventus Marker

Customized software solution

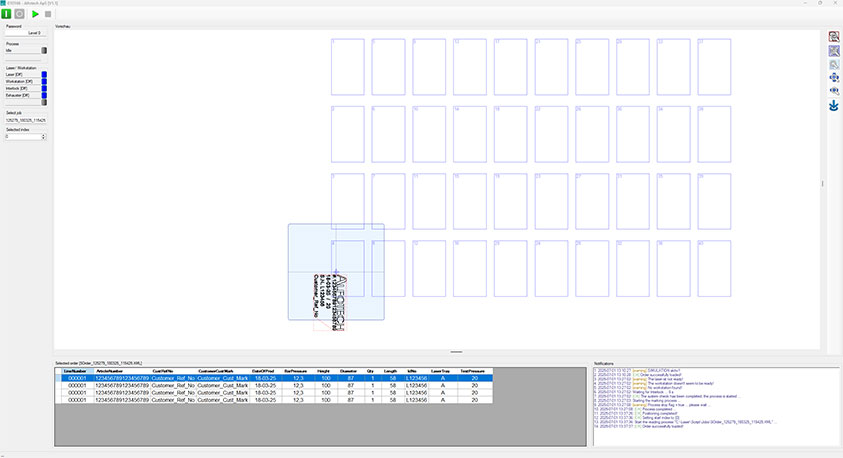

A unique selling point of the German laser manufacturer from Thuringia is the adaptability of the in-house Magic Mark V3 laser software to customer processes through individual programming. For the Alfotech project, ACI developed a graphical user interface (GUI) for the semi-automatic machining process.

Screenshot of the GUI shows the loaded data set for a job: four order lines for four pairs of workpieces

Semi-automatic operation with database connection

At the start of the process, the system operator loads the workstation with a workpiece holder. The press fittings are placed in the pallet in a predefined grid. The operator then uses a barcode scanner to read an ID that refers to a file with a data record as the data source. This file contains all the relevant data for marking. In the GUI of the customer software, each order line represents a line in the data record. Alfotech always processes the workpieces in pairs. This means that two components are always marked with the data from one order line. The data is imported from a database via the API of the Data Import Plugin from ACI. This gives the customer maximum flexibility when dealing with variable data in the marking process.

More efficiency and data security

The processing of the part pairs also requires suitable logic on the system side. This means that the workpiece positions that have already been successfully processed must be known at all times. Especially in situations where the marking process is properly stopped by the operator or the process is interrupted by an emergency stop, it must be known at which position and with which data set the processing must be continued.

To prevent the loss of the original labeling file due to accidental over-saving, only temporary copies are ever loaded when a data set is loaded. This increases data security in the production process and also helps to increase efficiency.