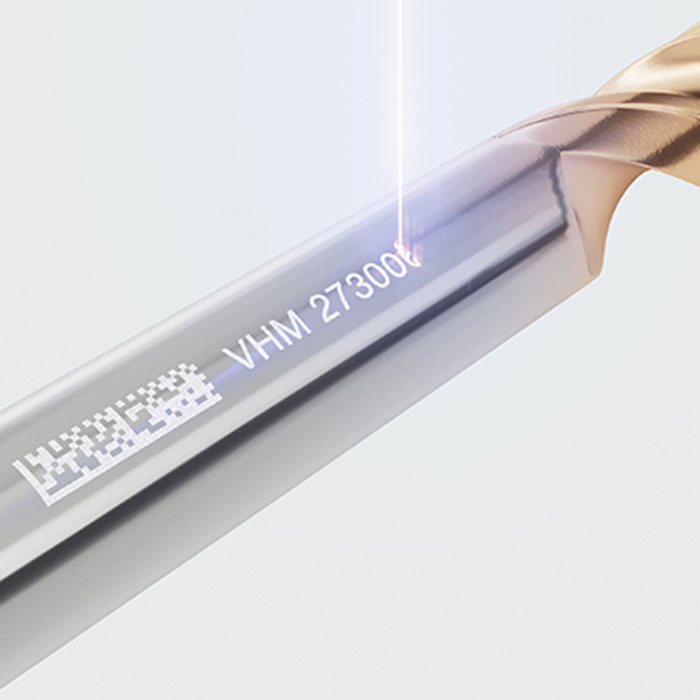

What is laser marking?

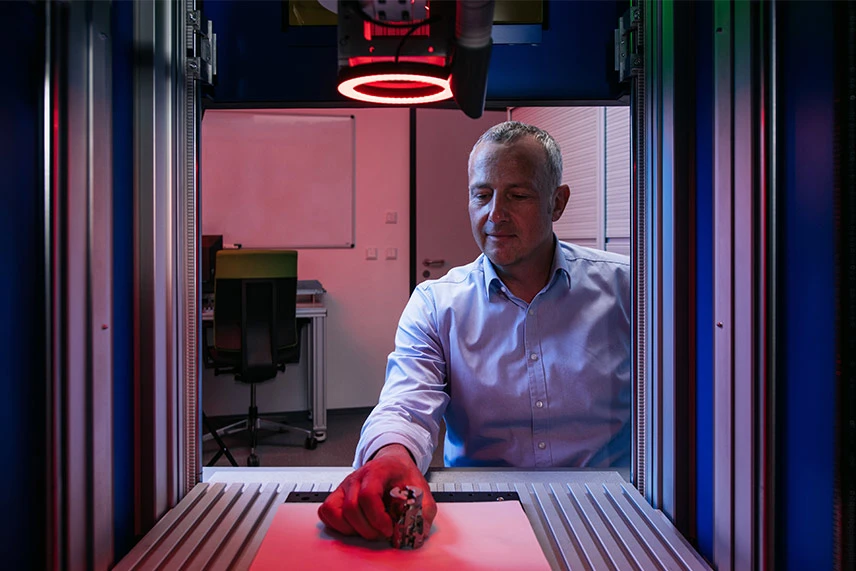

The AOI Vision System (Automatic Object Identification) was developed specifically for laser marking applications. It detects, identifies, and measures objects, text, and codes with high precision – directly in the marking area. The laser marking is automatically aligned and checked on the object. This ensures error-free results from the very first part – without any manual inspection.

| Automatic position detection – reduces operating effort and prevents misplacement | |

| Precise alignment of the marking – guarantees accurate results from the very first part | |

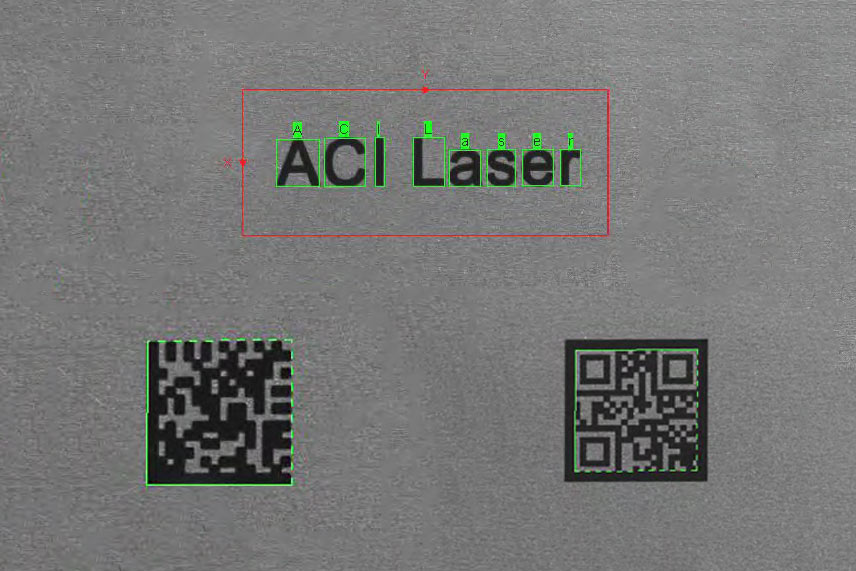

| Reading of 1D/2D codes and OCR texts – ensures traceability and quality | |

| Real-time inspection after marking – errors are detected immediately, avoiding rejects | |

| Management of up to 500 part types – ideal for series production with a high degree of variety | |

| Seamless integration into ACI laser systems – with AOI plugin and camera unit |

AOI aligns the marking precisely based on contours, edges, or features. Immediately after marking, the system checks the quality of the marking. This means there is no waste – even with changing parts or variable positions. As a result, every production step is documented in a traceable manner, which increases process reliability and supports compliance with norms or industry-specific standards.

Manual inspections quickly reach their limits when it comes to small components or codes that are difficult to read. The AOI vision system automates this step – regardless of location or position. This reduces the error rate, avoids rework, and ensures traceability. Especially in series production processes, this automation ensures consistent quality and relieves skilled personnel of time-consuming routine tasks.

Whether serial numbers, DMC, text, or freely defined characteristics – AOI recognizes the relevant elements and evaluates them directly in the process. 1D/2D codes and OCR character recognition are reliably read, checked, and documented. Ideal for applications with high traceability and quality assurance requirements. This means that even complex product lines with many variants can be efficiently secured – from individual parts to large series.

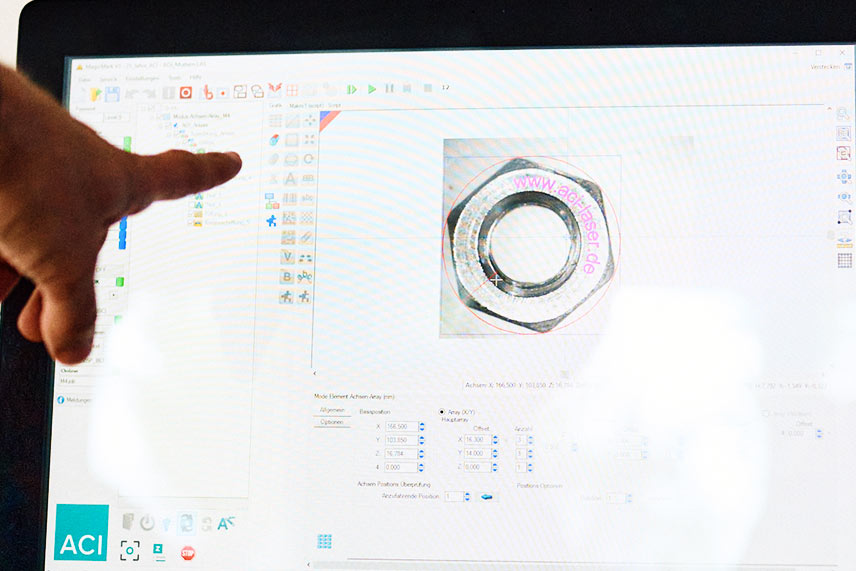

The AOI Vision system can be integrated into the ACI marking software Magic Mark as an optional plug-in. In combination with the camera unit, it enables central control of image processing, position detection, laser marking, and quality control – all via a common user interface. No additional external programs or interfaces are required. Direct integration into Magic Mark reduces complexity and enables rapid implementation during ongoing operations.

The compact system can be adapted to different geometries, tolerances, and camera resolutions. AOI can manage up to 500 different part types and delivers stable results – even for complex tasks. Integration into existing laser stations is quick and easy. This makes the AOI vision system suitable for both retrofitting and new systems, helping manufacturers to future-proof their processes.

The AOI Vision System is used for automated object recognition, precise alignment, and quality control in laser marking. It recognizes components based on contours, edges, or features, precisely aligns the marking, and checks the result immediately after the marking process. This prevents errors, reduces scrap, and makes processes safer and more efficient. The AOI Vision System helps manufacturers achieve consistently high product quality and reliably meet the demands of challenging manufacturing environments.

Compared to manual inspection, the AOI vision system significantly reduces the error rate. Manual visual inspections are prone to errors, time-consuming, and hardly reliable when it comes to small or difficult-to-read markings. AOI performs this step automatically—regardless of location, position, or component variety. This reduces scrap, avoids rework, and relieves the burden on skilled personnel.

The AOI vision system is optimized for a wide range of codes and characters. It reliably reads both 1D barcodes and 2D codes such as DataMatrix or QR codes. In addition, integrated OCR character recognition is available to check alphanumeric texts and serial numbers directly in the process. This makes AOI suitable for almost all common types of marking in industrial manufacturing – from component numbers and batch codes to safety-related markings.

The AOI Vision System can manage up to 500 different part types. Each type can be stored with specific parameters such as geometry, tolerance, alignment, and camera resolution. This is particularly useful in production environments with a high degree of variety, e.g., when many different components or product series are processed on one line. Switching between types is software-supported and does not require manual retooling.

Yes, the AOI Vision system requires both the optional AOI plugin and a hardware module (camera unit). The plugin is fully integrated into the ACI marking software Magic Mark, allowing image processing, position detection, and quality control to be controlled centrally via a single interface—without the need for additional programs or interfaces. The hardware module must either already be installed on the laser head or can be retrofitted.

Note: Magic Mark V3 build 500 or higher is required to use the AOI plugin.

The AOI Vision System can be integrated into the ACI Magic Mark marking software as an optional plug-in and is compatible with all ACI infrared laser systems, such as the laser systems in the following series: Business Fiber USP, Business Fiber, Economy Fiber, Business Diode IR, Economy Diode, and Business CO₂. In addition to the camera unit, Magic Mark V3 software build 500 or higher is required for retrofitting. The laser station must also have enough physical space for the camera unit. This means that AOI can be integrated into many existing systems without the need for a complete replacement.

Yes, the AOI Vision system can be retrofitted to many existing ACI laser stations. The retrofit includes both the camera unit and the AOI plugin, which is integrated directly into the Magic Mark marking software. A Magic Mark V3 build 500 or higher is required. This allows image processing, position detection, and quality control to be performed centrally via a common user interface—without the need for additional external software or interfaces. Implementation is straightforward and does not require extensive adjustments to the production environment. Companies can thus take advantage of automatic object recognition and quality control even retroactively, without having to invest in completely new laser systems.

Press ENTER to confirm or press ESC to close