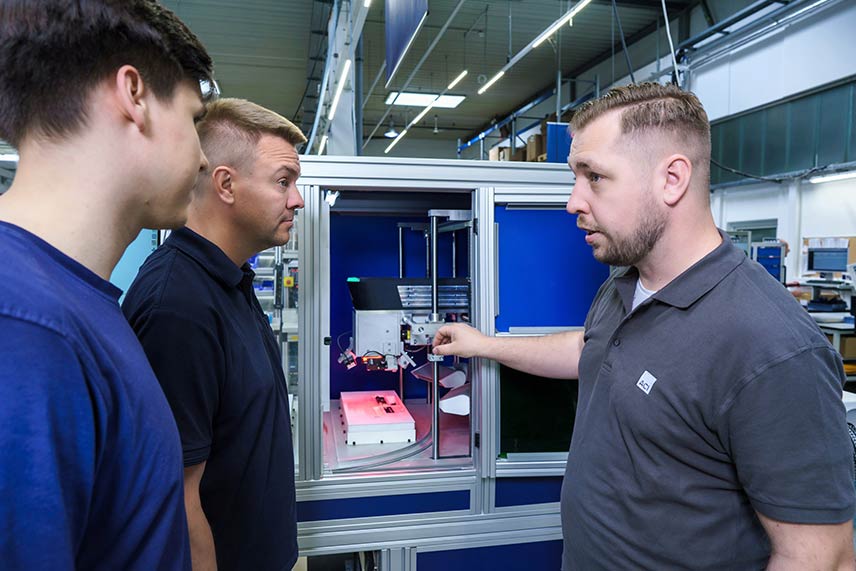

A satisfied ACI customer

| Material and process | DFL Nova Marker – Industrial Design |

|---|---|

| Temper the metal | |

| Engrave metal | |

| Remove metal | |

| Foam plastic | |

| Carbonize plastic | |

| Engrave plastic | |

| Foil removal | |

| Foil color cover | |

| Glass | |

| Ceramics | |

| Wood, paper, leather |

Precision and gentle treatment of materials in ultraviolet light

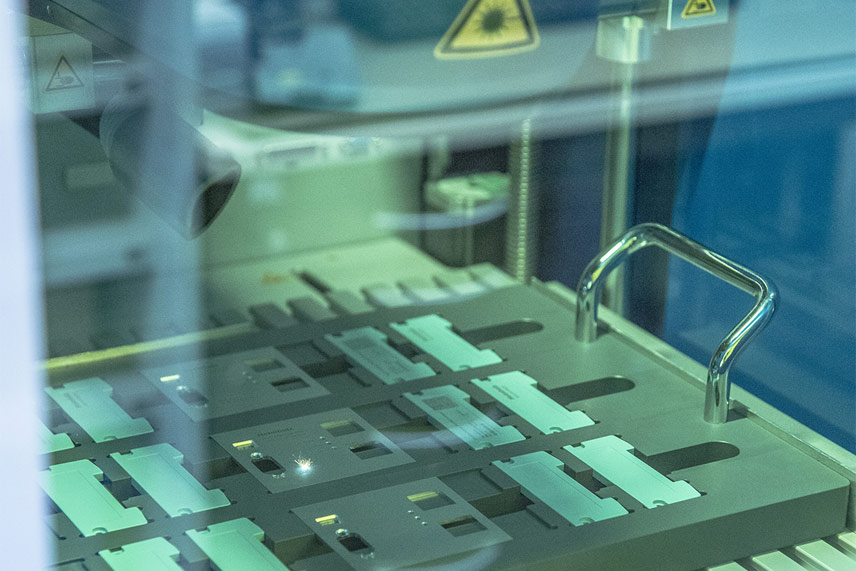

The DFL Nova Marker from the Business Fiber UV series is a highly specialized UV fiber laser with a wavelength of 355 nm, developed for applications where conventional laser systems reach their limits. Its extremely short pulse duration of 1.5 ns and high peak pulse power of up to 10 kW enable the finest engravings, structures, and cuts – even on sensitive materials such as plastics, ceramics, or glass.

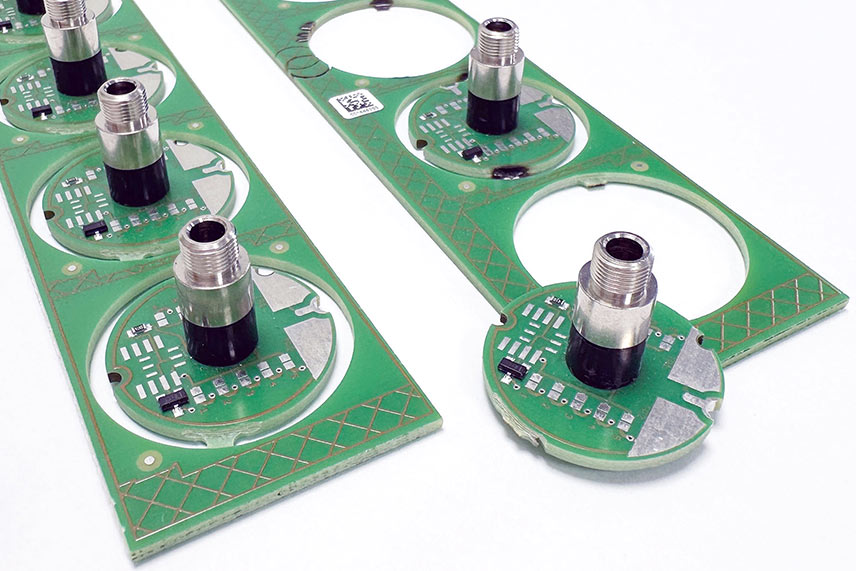

Whether you need to separate circuit boards without burrs, mark medical plastic parts with high contrast, or precisely microstructure copper, the Business Fiber UV delivers high-resolution results without thermally stressing the material or changing its properties.

| Material and process | DFL Nova Marker – Industrial Design |

|---|---|

| Temper the metal | |

| Engrave metal | |

| Remove metal | |

| Foam plastic | |

| Carbonize plastic | |

| Engrave plastic | |

| Foil removal | |

| Foil color cover | |

| Glass | |

| Ceramics | |

| Wood, paper, leather |

All laser systems are equipped with a safety device (SD) certified according to EN ISO 13849 in accordance with functional safety requirements, thus guaranteeing the user the highest possible protection against malfunctions and a safe condition of their laser system. (EN 13849 PLe Cat. 4).

The aim of marking a product or component is to create a label that is permanent, high-contrast, and high-resolution. In addition, it should place minimal stress on the material and cause minimal changes to its properties. These requirements are optimally met by the laser systems in the Business Fiber UV series.

| Gentle processing – UV wavelength prevents thermal damage, perfect for sensitive materials | |

| Fine structuring & panel separation – Precise cuts and structures on metals, circuit boards, and plastics | |

| Flexible integration – can be used as a manual workstation or seamlessly integrated into production lines | |

| Maximum safety – laser safety class 4, optionally also class 1 with laser station | |

| Smart control – with Magic Mark V3, expandable with plug-ins and external connections | |

The UV wavelength of 355 nm enables particularly gentle laser processing. Even sensitive materials such as plastic, ceramics, or glass can be marked with high contrast without deforming or losing their properties. The short pulse duration of 1.5 ns prevents unwanted heat effects. This results in permanent markings with maximum precision and minimal stress.

The Business Fiber UV is not only suitable for marking, but also for high-precision fine cutting and structuring. Circuit boards can be separated burr-free, and copper and aluminum can be structured with microscopic precision. The high peak power of up to 10 kW ensures clean cut edges. This makes the laser ideal for applications in microelectronics and medical technology.

The system is available as a tabletop device or 19-inch built-in device and can be flexibly integrated into existing production environments. Whether as a single workstation or as a module in an automated production line, the laser adapts to your requirements. The compact design and standardized interfaces facilitate integration. This keeps your production scalable and future-proof.

The DFL Nova Marker can be operated in combination with a suitable laser station in accordance with laser safety class 1. This means that the laser is completely enclosed and no laser radiation escapes to the outside – safe operation is therefore also possible in work areas that are not specifically shielded for laser applications. This protection class is particularly necessary in safety-relevant industries such as medical technology or at manual workstations.

Our Magic Mark V3 laser software offers full control over the laser and additional components. Predefined parameter sets are available immediately, simplifying setup. Programs can be created internally or externally, and functions can be expanded using plug-ins. The architecture is designed for industrial requirements and makes laser processing easy to control.

Press ENTER to confirm or press ESC to close