A satisfied ACI customer

Intelligent camera systems for precise laser processes

Precision begins with the right perspective

Precision begins with proper alignment and control: With vision and code reading systems from ACI Laser, you can expand your laser applications with camera-based intelligence. Whether automatic object recognition with the AOI vision system, precise alignment with the CPM vision system, or reliable code reading – our systems ensure that every marking is accurate, processes become more efficient, and quality remains traceable at all times.

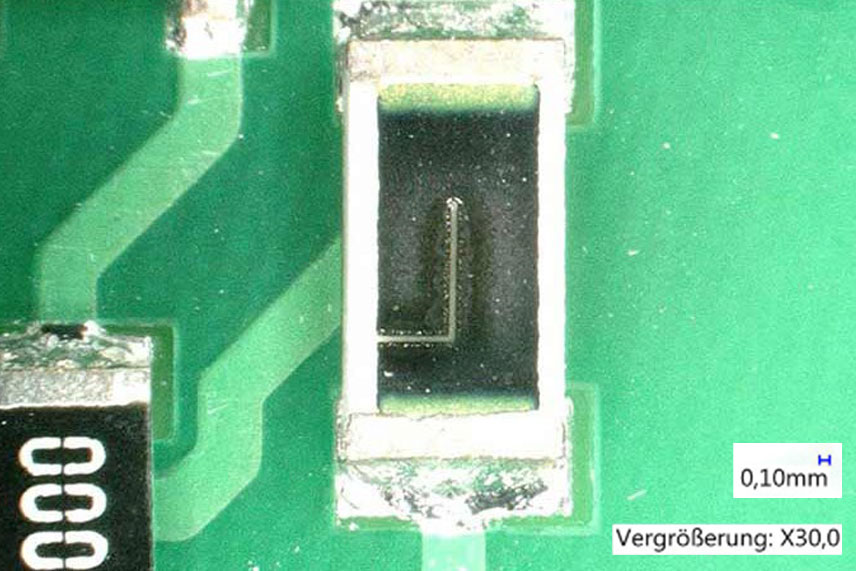

In addition, vision systems make a decisive contribution to error prevention and process reliability. They reduce the workload on operators, make processes reproducible, and increase efficiency – even with a high degree of variant diversity or complex components. In laser trimming, they enable precise positioning of the laser beam on electronic components such as resistors or conductor tracks. This allows conductance values to be set exactly – for stable, long-lasting, and standard-compliant results in electronics and measurement technology.

Error-free laser marking

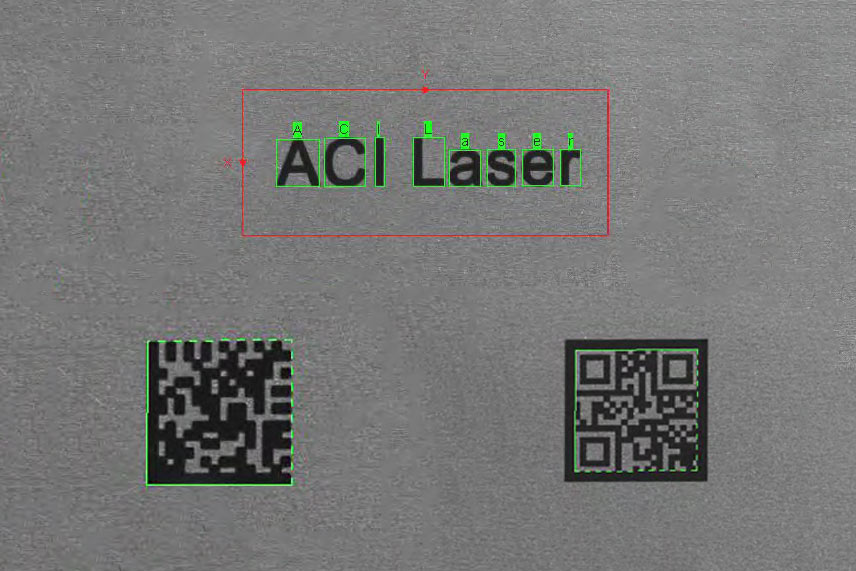

Error-free results thanks to automatic object recognition, precise alignment, and integrated quality control – ideal for series production with high requirements. The AOI vision system automatically places layouts on the workpiece, checks markings in real time, reduces scrap, and ensures traceability. Especially in environments with a high degree of variety, it ensures process reliability and consistently high quality.

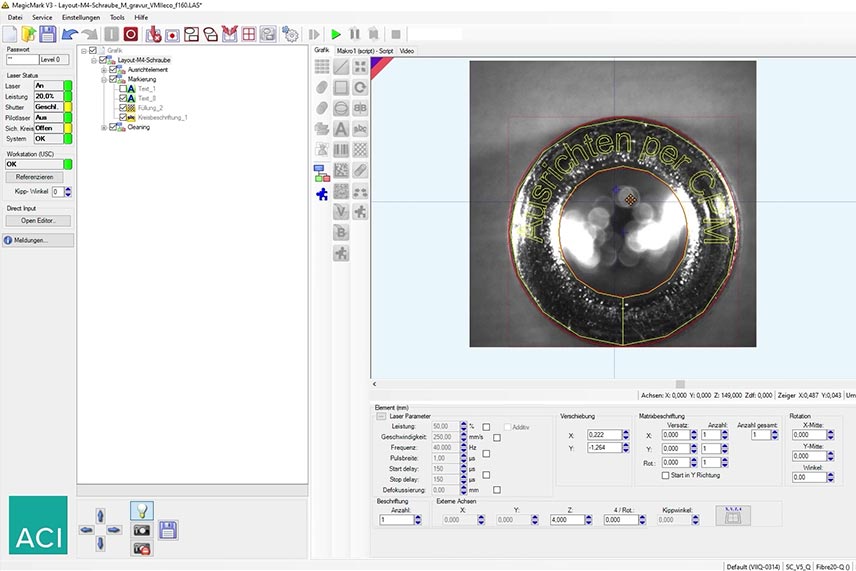

Precise positioning on the live image

Precise positioning thanks to live image and visual support – safety even before marking, especially with changing or complex objects. The CPM Vision system immediately shows whether the marking is exactly in place, thus preventing misalignment. It facilitates handling even with delicate structures and increases efficiency in everyday production.

Precision, safety, and efficiency for every application

Vision systems are now an integral part of modern laser processes. They not only ensure precise alignment of the marking, but also perform direct quality control and automatic reading of codes and texts. This allows processes to be standardized, sources of error to be reduced, and productivity to be increased.

Vision systems offer clear advantages, especially in demanding industries such as medical technology, electronics, and automotive: even the smallest structures, complex components, and changing batch sizes can be processed reliably. The systems ensure consistent quality, process reliability, and complete traceability – crucial factors in regulated and highly competitive markets. They are also indispensable in laser trimming: visual detection and precise alignment of the laser beam allow resistance values or switching parameters to be adjusted precisely – without damaging the ceramic body. This results in highly stable, precisely calibrated components for demanding applications.

Thanks to their close integration with ACI laser systems and software, vision systems are flexible in use and can be configured individually. Whether for series production, variable production, or special applications, they create measurable added value and make laser marking more efficient, safer, and future-proof.

Automatic position detection and quality inspection

The AOI vision system detects the position and orientation of the component based on contours, edges, or features. The marking is aligned accordingly and checked immediately after the laser process. This results in a continuous process with documented quality – without any manual readjustment.

Flexible for every marking job

Whether serial numbers, DataMatrix codes, or OCR characters: the systems capture and evaluate a wide variety of content directly in the process. This allows even complex product lines with many variants to be handled efficiently and reliably – from individual parts to large series.

Precise alignment in the live image

The CPM Vision system displays the component in real time and automatically adjusts the layout to the perspective and geometry. This ensures that the marking is placed exactly where it is intended – intuitively, visually verifiable, and ideal for complex shapes or small areas.

Targeted processing of electronic components

Laser trimming requires maximum precision: resistors, conductor tracks, and other functional structures must be machined with extreme accuracy in order to precisely adjust electrical properties. With Business Fiber TRIM, the AOI vision system supports this process through camera-assisted positioning and visual inspection. This guides the laser beam precisely to the desired location without damaging the component body. The result: stable, durable, and precisely calibrated components for demanding applications in electronics and measurement technology.

Vision systems such as CPM and AOI expand laser applications to include visual inspection, automatic alignment, and integrated testing. The CPM vision system supports precise placement of the marking in the live image, while the AOI vision system detects the component position and checks the marking immediately after the laser process. Code reading systems capture content such as serial numbers, DataMatrix codes, or OCR characters and evaluate them during the process. Together, these systems ensure accurate results, efficient processes, and documented quality – without the need for additional software or manual rework.

The CPM Vision system displays the component as a live or single image directly in the marking software. The marking is placed in the camera image – automatically corrected, adjusted for perspective, and precisely aligned with the actual object surface. This ensures maximum precision even before the laser process, without any manual adjustment. CPM ensures intuitive and reliable positioning, especially for complex geometries or small marking areas.

The AOI vision system analyzes the component based on contours, edges, or defined features. It then automatically determines the exact position and orientation. The marking is aligned directly to this – without any manual intervention. This creates a consistent, visually controlled process with reproducible results – even with changing positions or variants.

Laser trimming requires electronic components such as resistors or conductor tracks to be processed with the utmost precision in order to adjust electrical properties in a targeted manner. The AOI vision system detects the exact position and orientation of these structures based on contours or features and aligns the laser process accordingly. Processing is controlled and reproducible – without damaging the component body. This results in precisely calibrated components with stable properties, ideal for applications in electronics and measurement technology.

Press ENTER to confirm or press ESC to close