Challenges and solutions

Mark without roughening

Laser processing of ceramics poses a particular challenge, as the interaction between lasers and ceramics is usually complex. Precise laser engraving or laser marking on ceramics is therefore difficult. This complexity makes it necessary to process ceramics with specially shaped laser beams.

ACI has developed lasers for these applications that penetrate the material with a very sharp beam profile and achieve excellent results.

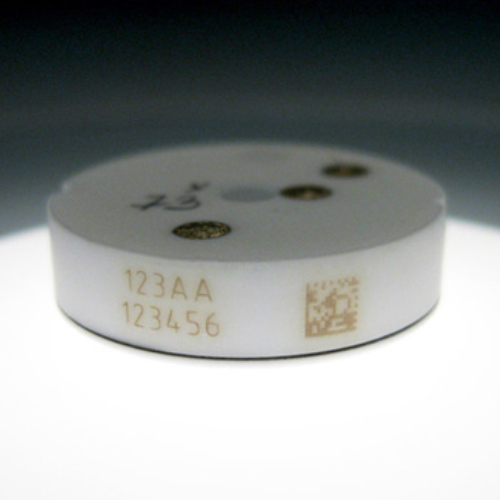

Unlike other processes such as etching or sandblasting, laser engraving does not roughen the surface of the ceramic, but melts it. This means that it does not provide any anchor points for contaminants and remains easy to clean, which is why the process offers significant added value, especially for medical and technical ceramics. Ceramic tiles and porcelain also remain easy to clean after laser engraving.

But regardless of whether you are working with tiles for bathrooms or high-performance ceramics for aerospace applications, laser engraving of ceramics allows you to produce high-resolution markings and complex geometries without the waste materials and tool changes associated with other processes. The laser offers you tangible added value in terms of throughput speed and environmental friendliness.

The convenient control of our laser systems not only guarantees high repeat accuracy, but also complete design freedom. With our intuitive Magic Mark V3 software, you can not only effortlessly create your own designs, but also control multiple lasers simultaneously if desired.

Ceramics are oxidic and silicate materials whose structure consists of crystals or a combination of crystalline and glass-like components. They are non-metallic, polycrystalline and inorganic. This group of materials includes clay ceramics such as stoneware and porcelain, as well as materials such as silicon carbide and tungsten carbide.

CO₂ lasers, UKP lasers or UV fibre lasers are the best choice for laser engraving ceramics, as they ensure high energy input into the material. However, some diode lasers are also suitable for ceramics.

Unlike laser engraving of plastics or metals, the processing of ceramics involves interactions between the laser and the material. This means that laser processing of ceramics can only be reliably carried out with the appropriate equipment. The experts at ACI Laser will be happy to advise you individually on this.

Press ENTER to confirm or press ESC to close