Support, Service & After Sales

We accompany you

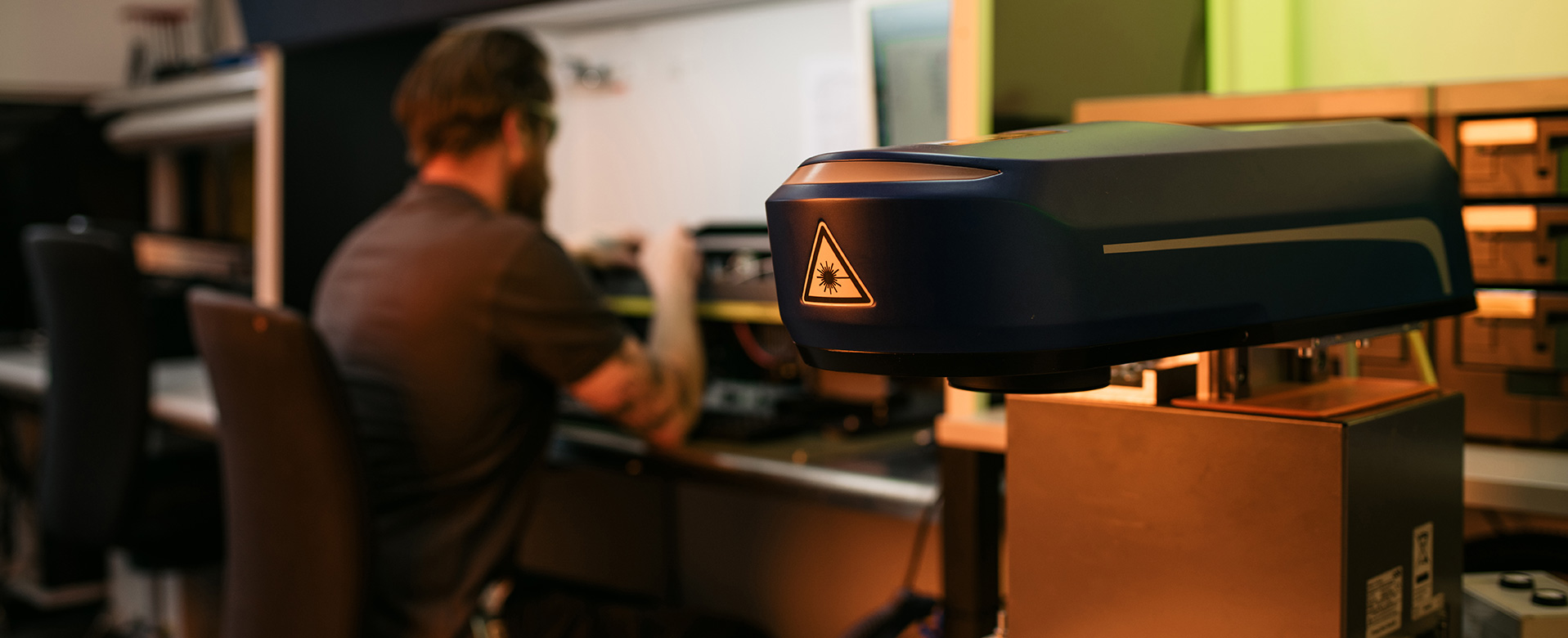

As a renowned manufacturer of lasers, laser systems, laser stations and laser software, ACI Laser not only offers you high-quality products, but also first-class support and services. So you can get the best out of your laser applications:

Our application specialists will be happy to help you find the optimum laser solution for your specific requirements. We develop customized solutions for your application.

Would you like to see in advance how our lasers process your materials? No problem! We are happy to produce samples so that you can see the quality and precision of our laser processing for yourself.

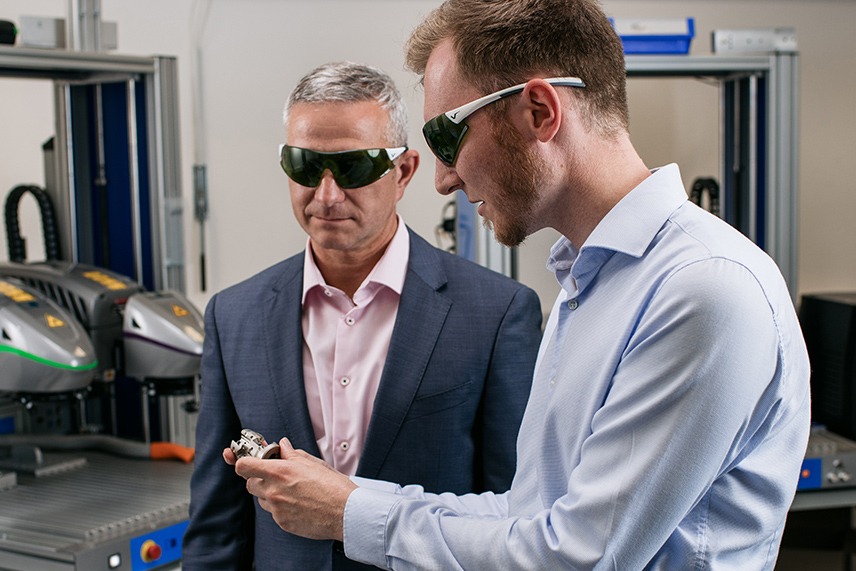

Are you interested in our laser systems? We offer system demonstrations where you can experience the performance and efficiency of our lasers live. Contact us today to find out more about our products and services. We are your reliable partner for all laser applications.

We offer training courses so that you can operate your laser systems effectively and safely. Our experts are happy to share their knowledge with you so that you can exploit the full potential of your laser solutions.

Our experienced technicians are at your disposal for the maintenance and repair of your laser systems. We ensure that your systems run smoothly and downtimes are minimized.

Our dedicated customer service team is always on hand to answer your questions and provide support. We pride ourselves on our first-class service and do everything we can to ensure that you are satisfied.

Press ENTER to confirm or press ESC to close